-

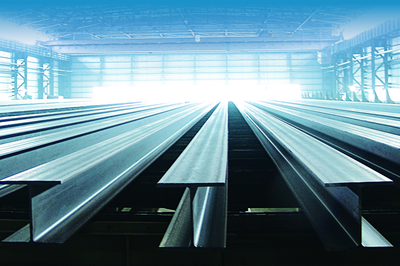

Hot Rolled U-shaped Steel Sheet PileDescription:

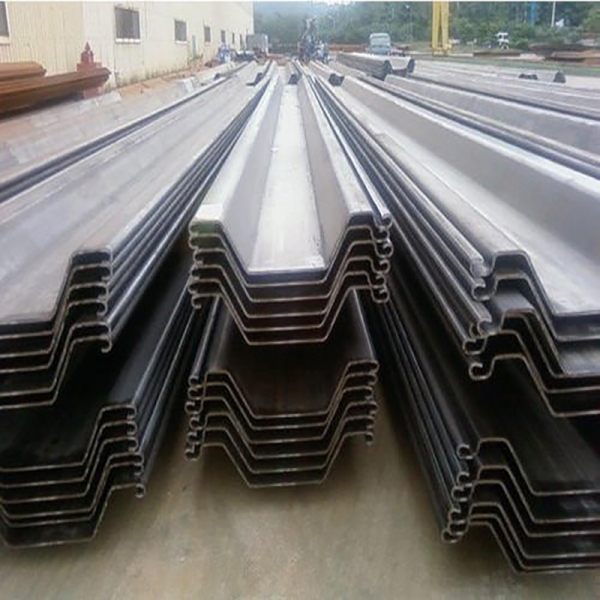

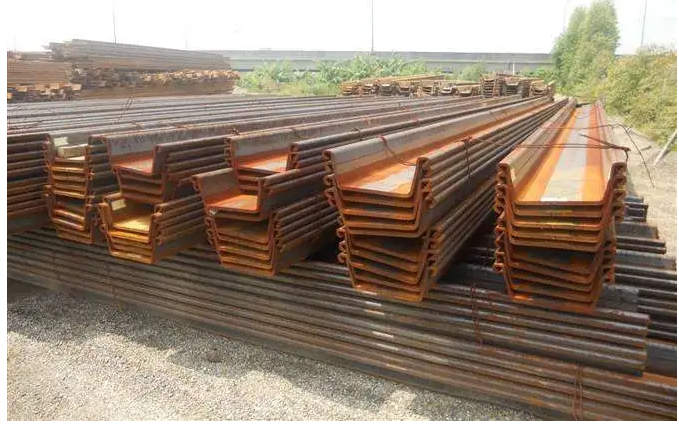

The U-shaped Steel Sheet Pile has been used for ground support for over 100 years, their versatility, reliability and strength has been paramount to their success and constant use in the construction industry.The thicker rolled flange and interlock design enable multiple reused making Hot Rolled U-shaped Sheet Piles a common choice for temporary works.

Liansen Metal offer a comprehensive range of hot rolled U-shaped Steel Sheet Piles. Currently stocking more than 30,000 tonnes, Liansen Metal can react efficiently and promptly to urgent requirements.

Specifications

Product Name

Hot Rolled U-shaped Steel Sheet Pile

Steel Grade

S275,S355,S390,S430,SY295,SY390,ASTM A690

Production Standard

EN10248,EN10249,JIS5528,JIS5523,ASTM

Length

Single Length Up To Over 80m

Certificates

ISO9001,ISO14001,ISO18001,CE FPC

Dimensions

Any Dimensions,Any Width X Height X Thickness

Interlock Types

Larssen Locks,Cold Rolled Interlock,Hot Rolled Interlock

Delivery Time

One Week,80000 Tons In Stock

More details of U-shaped Steel Sheet Pile

Item

grade and chemical composition

grade

C

SI

MN

P

S

V

Nb

Ti

CEV

Q295P

0.16

0.50

1.5

0.035

0.035

0.15

0.06

0.20

0.40

Q345P

0.20

0.50

1.7

0.035

0.035

0.15

0.06

0.20

0.42

Q390P

0.20

0.50

1.7

0.035

0.035

0.20

0.06

0.20

0.44

Q420P

0.20

0.50

1.7

0.035

0.035

0.20

0.06

0.20

0.46

Q490P

0.20

0.60

1.8

0.030

0.030

0.20

0.11

0.20

0.46

Advantages:

The advantages of U Hot Rolled Steel Sheet Piles are multiple: – A wide range of sections forming several series with various geometrical characteristics, allowing a technically and economically optimum choice for each specific project. – Combination of great profile depth with large flange thickness giving excellent electrostatic properties. – The symmetrical form of the single element has made these sheet piles particularly convenient for re-use. – The possibility of assembling and crimping the piles into pairs at the mill improves installation quality and performance. – Easy fixing of tie-rods and swiveling attachments, even under water. – Good corrosion resistance, the steel being thickest at the critical corrosion points.

- Jinxi Group

- Jinxi Group

- WhatsApp

- Home

- Company Profile

-

hot Products

- Jinxi Group conscientiously implements the national industrial policies, extends the industrial chain, and solidly promotes transf

VIEW >>

-

Products

- Jinxi's main products are H-shaped steel, steel sheet pile, electrified railway contact line pillar steel, channel steel, Angle st

VIEW >>

-

News

- All our Latest News are Here. Wuxi liansen Metal aims to share our hard earned knowledge on carbon steel and stainless steel man

VIEW >>

- Contact Us